FOUNDRY BUSINESS IS OUR PROFESSION

We are able to operate in many industrial sectors by applying in aluminium casting the most advanced operating techniques in addition to a qualified staff, which, especially for sand castings, requires high experience and manuality.

In our foundry we use high technology techniques and instrumentation that allow us to reach a fundamental goal, the accuracy.

WHO WE ARE

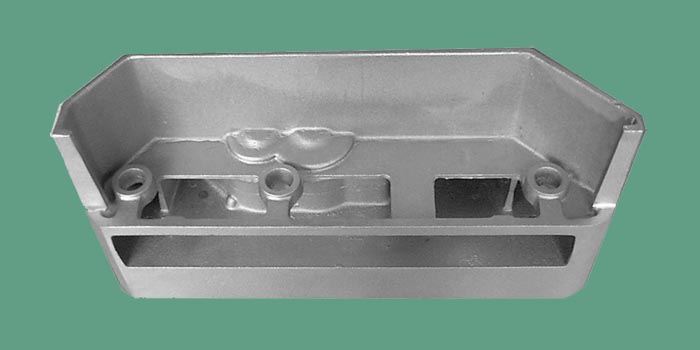

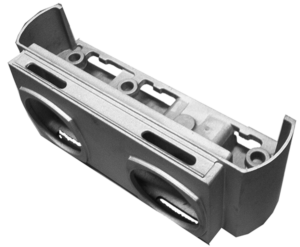

The production is aimed to all mechanical industry sectors, in particular automotive, industrial, naval and it focus mainly on items that require high quality standards: engine mounts, transmission boxes, pumps, automotive hydraulic distributors, compressors and castings related to mechanical, agricultural, textile and naval sectors.

Furthermore, over the years, we have been working in the field of arts, furniture and lighting.

Parts are supplied to our customers both raw or machined, lack tested, painted and assembled, thanks to our qualified partners.

OUR CASTING TECHNIQUE

The Ortimini Fonderia works with various aluminum alloys:

- Aluminum with silicon primary formulation alloys.

- Aluminum with magnesium primary formulation alloys.

- Aluminum with nickel primary formulation alloys.

- Copper-zinc primary formulation alloys.

- Aluminum silicon alloys.

- Aluminum copper alloys.

Ortimini Fonderia bases its production on three different processes:

- Automated green sand casting.

- Manual green sand casting (for bigger parts).

- Die casting.

COMPANY HISTORY

Ortimini Fonderia was founded in 1958 as a fact company, then managed from 1972 to 1991 as a family business where the current members were already present. In 1991, the Fonderia Ortimini Alvaro, was formed as limited liability companies. Both partners have over forty years of experience in this business sector. In recent years, the demand for productive growth and qualitative improvement has led the company to switch from manual shaping to fully automated forming systems. This technologically advanced process, which is carried out at our San Gimignano facility, allows us to provide our customers with superior quality products at lower prices and shorter delivery times.

WHAT WE DO

Based on the customer’s requirements we can work with various aluminum alloys.

Each machining is carefully followed by our company specialized department.

Our staff follows a careful and professional way to achieve the highest quality.

There is also a department dedicated to deburring, sandblasting and mechanical machining of various kinds.

Our products range extends to many areas such as Furniture, Construction, Mechanics, Cars, Naval, Wheelchairs, Pumps, Reducers, Molds, Textiles.

Each process is followed carefully by specialized departments. Our staff follows a careful and professional way to achieve a high quality product.

Ortimini Fonderia bases its production on three different processes:

CONTACTS

ORTIMINI FONDERIA SRL

Headquarters:

Via Fonte di Campaino, 20/22 53037 San Gimignano (Siena), Tuscany, Italy

Phone: 0577945013

Fax: 0577945921

E-mail:

vendite@fonderiaortimini.com

amministrazione@fonderiaortimini.com

Business hours: Lun – Ven; 9.00 – 13.00 ; 15.00 – 18.00

How to reach us:

For those coming from the highway connection A1 Firenze Siena exit at Poggibonsi and follow for Certaldo, when you are near the town center, follow for Sangimignano.

For those from S.G.C. FI-PI-LI exit at West Empoli and follow for Certaldo, when you are near the town center, follow for Sangimignano.